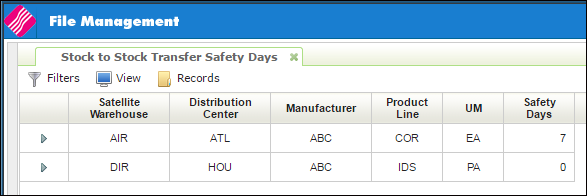

Stock to Stock Safety Days

This file, along with the Stock to Stock Safety Transfer Rules and the Stock to Stock Branch Transfer Reorder Parameters files are used to set -up the Stock to Stock Transfers Reorder Report. The Branch Reorder Report automates the process of calculating and entering transfer orders.

Prior to the introduction of these files and the Stock to Stock Transfers Reorder Report in 2012, branch managers or purchasing agents had to manually research inventory needs and then enter the transfer orders.

The Stock to Stock Safety Days for Distribution Center allows you to set up a safety stock by Manufacturer and/or Product Line for the Distribution Center.

Safety stock defines the inventory level beneath which the branch transfer process will not allocate inventory in the distribution center. Transfers will not be made that drives distribution center inventory level beneath this value.

To determine if the stock in the Distribution Center will go under the entered Safety Days, the system looks at:

- The date span of the transfer order.

- The open order file to see if there are any other orders for the Manufacturer and Product Line.

- The average daily usage for the inventory being ordered.

To calculate average daily usage the system checks the Stocking Matrix File. If the distribution center is listed as the Replenish To value on a record with *** in the Shipped From field; calculate usage based on all warehouses (excluding DIR). Otherwise calculate usage only for speÂcific warehouses listed in Sold From field of all records with DC warehouse in the Replenish To field.

If no Stocking Matrix records are found then calculate usage using the distribution center warehouse value only.

How the System Checks for Safety Stock at the Distribution Center

- The Branch Transfers Reorder report evaluates daily usage for specific items and tests the availÂable inventory in the Distribution Center to determine if it is already below the safety stock level (# of days x average daily usage).

- If its not below the safety stock level, the system determines if the transfer results in a new availÂable quantity in the DC that is below the safety stock level.

- If either case is true, the transfer will not be created and the report will indicate that transfer would have pushed inventory below DC safety stock levels.